Heat treatment represents a critical stage in the manufacturing of metallurgical components, typically occurring midway through the production process. A failed heat treatment can invalidate both preceding and subsequent processes, leading to significant losses in resources, time, and energy. Quality control systems in heat treatment are essential to ensure that components achieve the required mechanical and structural properties, thus avoiding costly rework and high scrap rates.

The Importance of Quality Control in Heat Treatment and Surface Finishing

From a quality assurance perspective, heat treatment is considered a «special process», which necessitates the implementation of strict controls at all stages. Its importance is tied to several key factors critical to modern metallurgical industries. Materials that appear similar may behave differently during heat treatment, requiring specific parameters to achieve the desired results.

The final mechanical properties of metallic components directly depend on the microstructural transformations induced during heat treatment. Steel derives its fundamental properties from its basic lattice structure, the forming process, and the microstructural changes caused by the controlled application of heat. Proper heat treatment—based on diffusion and phase transformation governed by precise time and temperature parameters—is essential for most engineering components destined for demanding applications..

Stages of Quality Control in the Heat Treatment Process

Quality control in heat treatment is structured around three fundamental stages, each with specific methodologies and objectives:

- Pre-treatment Control: Includes material characterization, chemical composition analysis, hardenability testing, and process parameter planning

- In-process Control: Involves continuous monitoring of critical variables such as temperature, holding time, heating and cooling rates, and furnace atmosphere conditions.

- Post-treatment Control: Comprises evaluation of resulting properties through hardness testing, metallographic analysis, and verification of required mechanical characteristics.

This structured approach ensures quality at every phase of the process, minimizing risks and optimizing outcomes..

Pre-treatment Control Methods

- Material characterization and chemical composition.

A material’s response to heat treatment is directly related to its chemical composition. Accurate verification of chemical composition enables optimal process parameter selection and allows anticipation of the microstructural transformations that will occur.

This information is vital for determining critical temperatures, suitable quenching media, and necessary holding times to achieve the intended transformations. - Hardenability testing

Hardenability—defined as the steel’s capacity to form martensite (or bainite) during cooling—is a key property to evaluate prior to heat treatment. The most recognized method is the Jominy end-quench test, which produces a hardenability curve for the material.

Hardenability should not be confused with hardness. While hardness refers to a material’s resistance to indentation, hardenability measures the depth to which a specific hardness can be achieved after surface cooling. This parameter is primarily influenced by carbon content, although alloying elements can reduce the cooling rate required for martensite formation. - Preliminary trials and Validation

Before processing full production batches, it is essential to carry out preliminary trials on sample pieces. These tests assess the actual behavior of the material under expected conditions, allow for parameter adjustments, and help identify potential issues.

In-process Control Methods

Temperature is arguably the most critical parameter in any heat treatment. Its control must be precise and cover three key aspects:

- Process Temperature: Monitored using thermocouples placed strategically in the furnace and on test pieces..

- Heating Rates: Controlled to prevent excessive thermal gradients that could cause internal stresses and distortion.

- Holding Times: The duration for which the material remains at treatment temperature must be sufficient to complete the desired microstructural transformations.

Modern systems employ PID (Proportional-Integral-Derivative) controllers that follow pre-set temperature curves with high accuracy, recording data for later analysis and traceability. However, each type of heat treatment demands control over specific variables.

Heat Treatments in Furnaces: The ky role of Atmosphere Control

The composition of the furnace atmosphere plays a decisive role in surface reactions during heat treatment. Oxidizing atmospheres may lead to surface decarburization in steels, while carburizing atmospheres can increase surface carbon content.

Common atmospheric issues include edge decarburization, insufficient carburization, and poor atmosphere quality. Modern systems use oxygen sensors, gas analyzers, and advanced control systems to maintain optimal and consistent conditions throughout the thermal cycle.

For aerospace-grade steels and tool steels, vacuum furnaces are used to minimize oxygen presence, thereby avoiding decarburization and undesirable oxidation of titanium and nickel-based alloys.

Post-treatment Control Methods

Once heat treatment is completed, it is essential to verify that the required properties have been achieved using various testing methods.

- Visual and Dimensional Inspection

Visual inspection serves as a first-level control to detect surface defects such as cracks, warping, or discoloration indicative of processing issues. Dimensional checks assess possible geometric distortion caused by thermal stresses. Severely deformed parts may require post-treatment straightening.

- Hardness Testing

Hardness testing is the most common method for verifying heat treatment effectiveness. Depending on the treatment type and component characteristics, various methods are employed:

1. Surface Hardness: Often measured using the Rockwell C scale for deep-hardened layers or superficial hardness methods for thinner layers.

2. Hardness Profiles: In surface treatments like carburizing, nitriding, or induction hardening, it’s critical to determine hardness variation from the surface to the core. This involves hardness or microhardness measurements along a cross-section. Values are compared with specifications to ensure compliance.

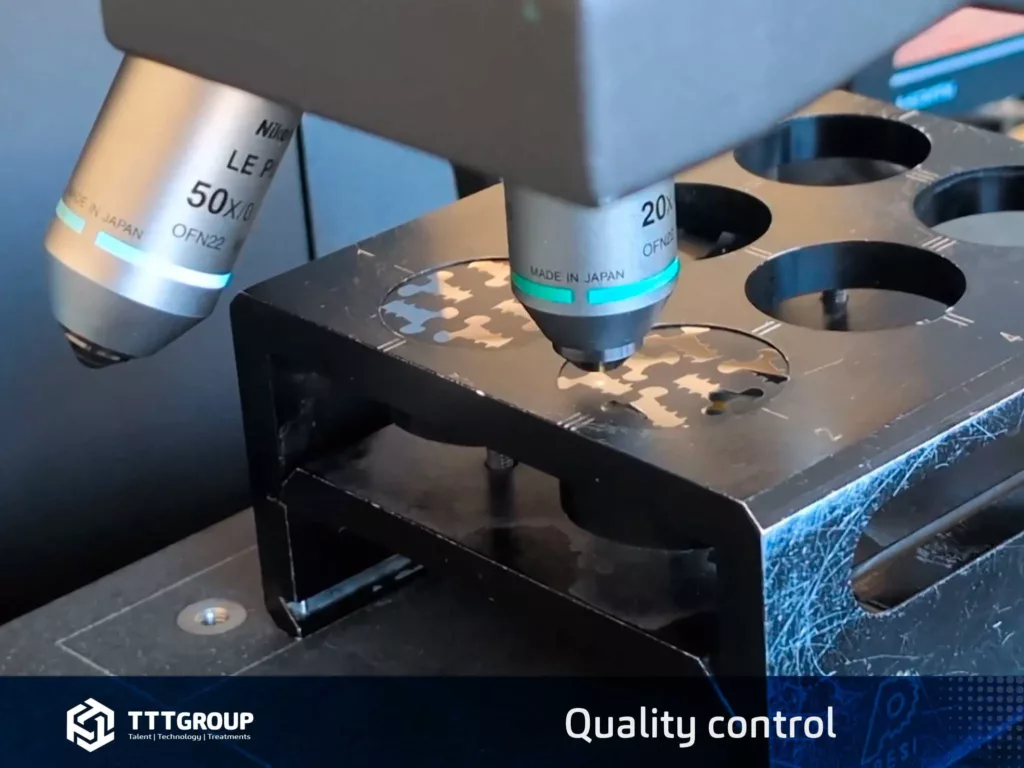

- Metallographic Analysis

Microscopic examination of the metallographic structure provides detailed information about phase distribution and characteristics. This analysis confirms whether the intended microstructural changes have occurred.

In quenching, for example, martensite may appear as needles, thin plates, or lenticular forms. Tempering modifies this morphology, producing tempered martensite structures better suited for mechanical applications. Metallographic analysis can confirm these transformations and detect issues like excessive grain growth or unwanted phases.

- Case Depth Evaluation

In surface treatments such as flame or induction hardening, verifying the depth of the hardened layer is essential. This typically involves cutting the part and measuring hardness at various depths or observing microstructural changes under a microscope. Since this is a destructive test, it is usually conducted on representative test pieces processed under identical conditions.

Critical Factors in Heat Treatment Quality Control

The quality of heat treatment processes depends on multiple interrelated factors, including:

- Material Specificity: Even similar materials may require different parameters due to variations in composition or initial microstructure.

- Component Size and Geometry: Size significantly impacts results, often requiring process parameter adjustments or custom tooling. Geometries with sharp edges or sudden thickness changes are prone to cracking and should be avoided.

- Personnel Qualification: Operators must have solid technical knowledge and practical experience to correctly interpret results and make informed decisions.

A comprehensive approach that considers all these factors, combined with strict control at every stage, forms the foundation for consistent, high-quality outcomes.

Effective quality control in heat treatment brings substantial economic benefits that justify investment in advanced systems and methodologies. A failed heat treatment renders all previous and subsequent processes useless, generating added costs for rework and waste management. Furthermore, as heat treatment is an energy-intensive process, quality issues directly impact energy efficiency and operational costs. In contexts with limited resources or supply constraints, optimizing material usage and treatment efficiency becomes crucial. Implementing robust quality control systems enables resource optimization through:

- Reduction in Rejected Parts: Early detection of deviations minimizes the need for rework or scrapping.

- Energy Optimization: Accurate temperature and time monitoring allows for thermal cycle adjustments to maximize energy efficiency without compromising quality.

- Process Standardization: Detailed documentation of parameters and outcomes facilitates reproducibility and continuous improvement.

- Development of Optimized Process Sheets: Enhancing process sheets based on hardenability tests helps refine treatment parameters.

Summary

Quality control in heat treatment processes is fundamental to ensuring that metallic components meet their required mechanical and microstructural properties. Implementing rigorous, systematic control methods before, during, and after heat treatment minimizes failures, optimizes resources, and ensures consistent results.

Control methods must be tailored to the specifics of each treatment type and material, accounting for chemical composition, hardenability, geometry, and end-use. Verifying critical parameters such as temperature, time, heating/cooling rates, and furnace atmosphere—alongside post-treatment hardness and metallographic testing—forms a comprehensive system to ensure final product quality.

The economic impact of heat treatment quality control strongly supports investment in advanced monitoring systems, personnel training, and optimized methodologies. In an increasingly competitive and technically demanding industrial landscape, such implementations enhance both product quality and the economic and environmental sustainability of metallurgical processes.

TTT Group has established a strong position in the heat treatment sector through systematic quality management and continuous process improvement. In an industrial environment where dimensional accuracy, repeatability, and traceability are critical, obtaining and maintaining certifications and accreditations is essential.

With a fully equipped testing laboratory, our heat treatment quality control system has earned the company the industry’s leading certifications, verifying compliance with international standards for quality, environmental management, and special processes.

Furthermore, TTT Group is an approved supplier for major aerospace manufacturers, with technical procedures validated by external bodies and highly demanding clients. These accreditations not only confirm our technical competence but also ensure our processes conform to the highest standards in industrial heat treatment.